Due to the scarcity and delicacy of cashmere fiber, the production line, production environment, professional team, and technology requirements of cashmere are more stringent than ordinary yarns.

Careful Technology

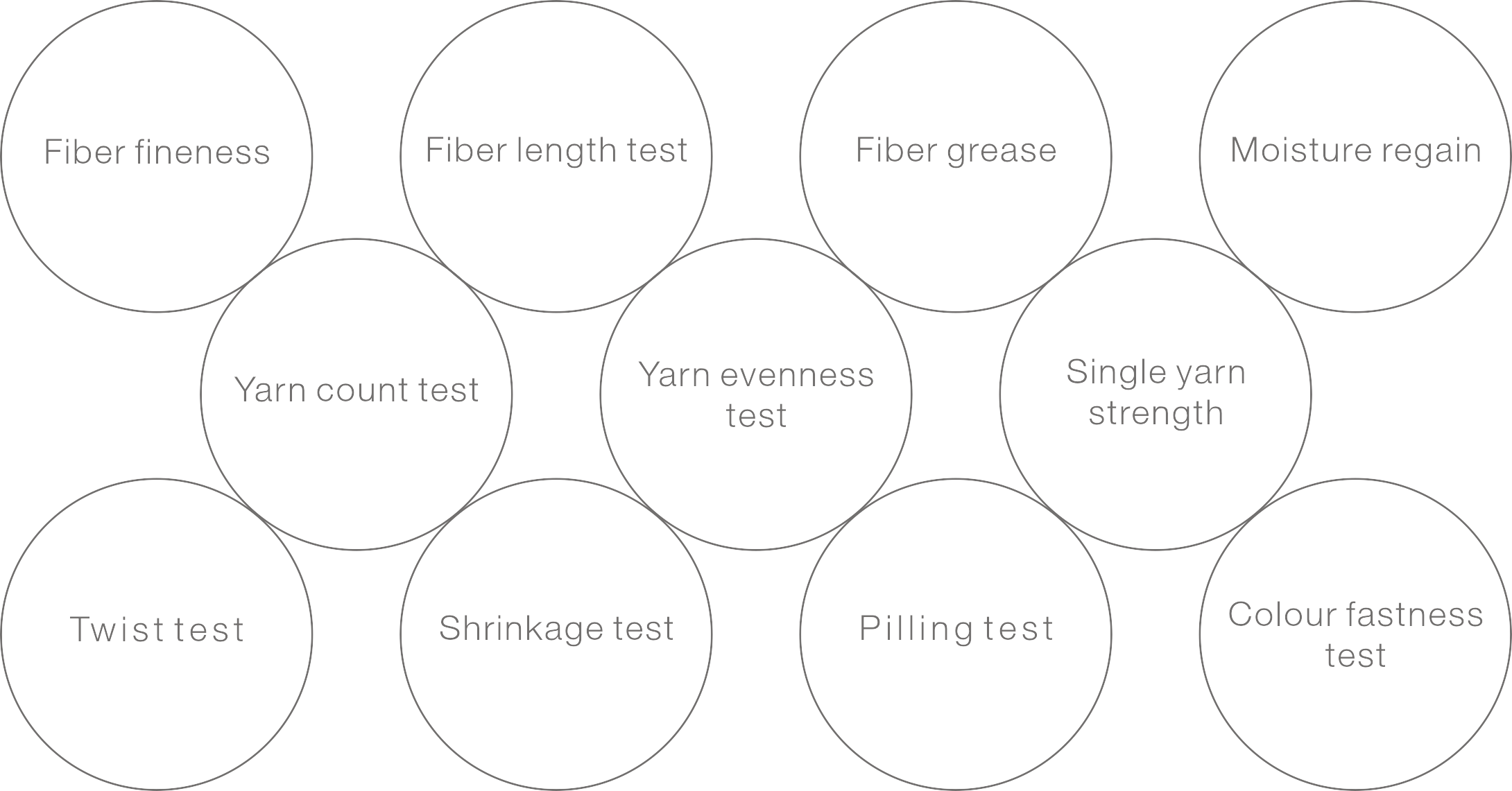

YILEI implements standardized management. In the process of worsted cashmere weaving, every link needs to be tested accordingly.

Cashmere raw materials need to pass the loose wool test. Only the standard velvet can enter the production process. At the same time, moisture regain test, evenness test, twist test, shrinkage test, anti-pilling test and color fastness test are through the entire production line, to realize the whole process of quality testing for ensuring all kinds of qualities of refined cashmere weaving, experience feeling of fabrics and fabric maintenance.

YILEI insists on adopting a higher standard and continues to provide more reliable refined cashmere products.

Lean Technics

YILEI imports the whole cashmere production line, equips the supporting dyeing factory and production workshops of constant temperature and humidity, and introduces the engineers who have decades of experience in cashmere production to build a first class and professional team. Besides, it uses exquisite techniques of combing and worsted spinning to keep the native characteristics of cashmere at utmost, and gives features of delicate and fashion.

Any negligence in the spinning process will result in fiber damage, thereby affecting the quality and feel of the product.As meticulous work makes fine quality, in order to reduce the loss of cashmere fiber, YILEI adopt mild pre-spinning process with slower rate to better protect delicate cashmere fibers.

The yarn needs to be twisted. And the cashmere yarn has higher requiements for twist.Twist has a direct effect on yarn structure, physical properties, even fabric style and finished product performance, from this, YILEI emphasis on the control of twist, striving to achieve the perfect standard through proofing and testing time after time.

YILEI production workshops have a sophisticated constant temperature and humidity system that can monitor the ambient temperature and humidity digitally so that the fibres seem to return to the best natural climate, fully recover the performance and restore the unique quality.

In the spinning process, each of the previous processes will cause the fiber tension effect, tension will cause yarn entanglement.The steaming process has the function of setting, when heated to a specified temperature, steam easily penetrates into the inside of the yarn, and releases energy during condensation, thus effectively reducing the internal stress of the yarn, to achieve better results.

The wet process in spinning can moisten the worsted cashmere, let the yarn have a suitable moisture regain to weave easily.

YILEI’s Craftsmanship

Even if industrialization has swept the traditional cashmere industry, but the true cashmere craftsmen still treat and process the fibers with aristocratic blood with an almost reverent attitude.Each person in YILEI owns the craftsmanship and they focus on their work, and their attitude towards perfection determines the quality of cashmere.

“All the valuable and related to beauty things will have assistance.” Cashmere is no exception. YILEI introduces the engineers who have decades of experience in cashmere production to build a first class and professional team working on a better tomorrow of cashmere.

With the spirit of originality, YILEI aims to be a standard of textile industry.

YILEI is one of the drafting units of the super high-count combed cashmere knitting yarn state standard and has participated in setting the Zhejiang Standards of “fashion cashmere knit coat”.

.jpg)